How does RepRap work?

All machines which use RepRap as their basis are designed around two parts. The print bed is the level surface on which a model will be created, one two-dimensional layer at a time. Above the print bed is the print head or ‘hotend’.

Feedstock, usually in the form of a thin plastic wire or filament, is pushed through the hotend – also known as the extruder – and melted and then squeezed through a narrow hole at the end. As the head moves over the bed, it draws a flat picture or 2D layer. The head then moves up a fraction of a millimetre (or the bed moves down) and the next layer is created on top.

Rinse and repeat.

Originally, many parts like the hotend were homemade by printer owners. For example, hollowed out bolts with a charge applied make a perfectly acceptable nozzle for melting plastic. As 3D print tech has taken off, however, commercially available parts are generally as cheap and higher quality as making them yourself.

What can 3D printers print?

Industrial 3D printers can handle just about any materials nowadays. Plastics, metals, foodstuffs and even cellular structures have all been 3D printed. RepRaps are pretty flexible too: they’ve also been used for creating unique designs out of chocolate, recycles polymers, metals and more. Mostly, though, hobbiests stick to two key materials.

- ABS (Acrylonitrile butadiene styrene) is the same plastic used for LEGO bricks. This has a high melting point (around 220° C) and is very rigid. It can be tough to print with since models can warp or crack as they cool at the bottom, so it’s recommended you use a heated print bed while working with ABS.

- PLA (polylactic acid) is made from vegetable starch (usually corn or potato). It has a lower melting point (around 170° C) and is fully biodegradable. It’s tougher than ABS, but can warp over time due to the low melting point. It’s a great, cheap material to work with.

Both ABS and PLA are readily available at around R350 a kilo in South Africa, and a kilo goes a long way. It comes in two diameters – 3.5mm and 1.75mm. The one you want depends on your hotend – a smaller nozzle requires thinner filament to prevent blockages forming.

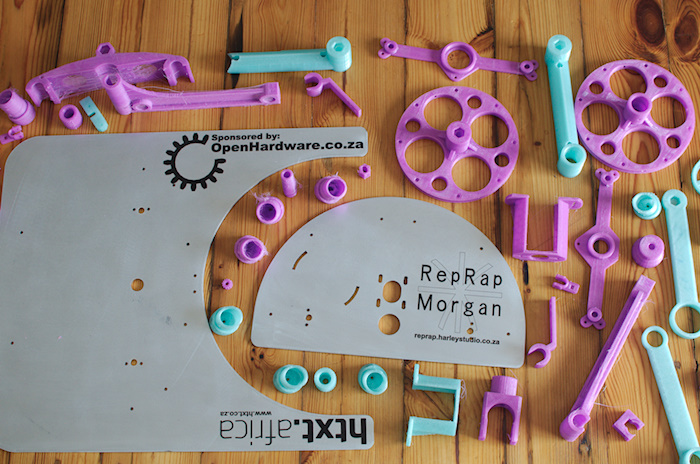

What is RepRap Morgan?

Morgan was designed by Quentin Harley, an engineer from Centurion. Harley’s design mounts all the familiar RepRap parts onto a SCARA arm which moves through both the x and y axis rather than the more usual floating x-axis design of earlier RepRaps. The reason is that more of Morgan’s parts can be printed, as it requires fewer metal rods for rigidity. That makes it cheaper to build and – thanks to some cunning design tricks – easier too.

How long does it take to print something?

That really depends. To produce all the parts required for the RepRap Morgan using an older Prusa Mendel 2 machine took us about two weeks, working mostly in the evenings. The larger parts, like the arms, required a couple of hours per piece, smaller bits can be printed in batches for extra speed.

(I’ve made a complete chess set based on an early 20th Century Bauhaus design, which took a week of on and off printing.)

You can alter the print speed, but generally speaking the faster you print the lower the quality of the final model. Morgan can typically print about a third again as fast as an older RepRap with no loss in quality.

How hard is a 3D printer to maintain?

I think of myself as a fairly tech savvy guy, but it took me the best part of 18 months to build a RepRap Prusa Mendel 2 and learn how to use it properly. And by use it properly, I mean figure out how to stop filament jams and learn how to remove them when they happened; quickly calibrate the print bed every time I unstuck a model and moved it slightly; adjust a Pololu driver without frying it; and start adding my own bits so that the printer behaves exactly how I want it to.

Once you’ve cracked all that, though, it’s easy.